By Brooke Lappe & Penelope Helm

Facts & Analysis

Over the past fifty years, the growth of plastic production and use and the shortcomings of plastic recycling have combined to create a major plastic problem. Most plastics are made from petrochemicals, particularly shale gas, to create a durable and strong product. These same qualities threaten the Earth. Almost all commonly used plastic is not biodegradable. Plastic production resulted in 450 million metric tons of greenhouse gases in 2021, and when consumers are done using plastic products, plastic trash sits in landfills, pollutes the environment, and endangers wildlife.

Forty-four million tons of plastic waste was generated in the United States in 2019, and that number continues to grow. That averages out to almost three hundred pounds of plastic waste per person. Only five to six percent of plastics are recycled. Plastic recycling is challenging for many reasons, including difficulties collecting and sorting material, plastic that contains toxins, and high economic cost. The failure of plastic recycling to keep up with growth of plastic waste has resulted in billions of tons of plastic waste that will not be recycled, will not biodegrade, and will continue polluting the Earth for eons. This problem has spurred an increase in research and development of technologies to recycle plastic waste.

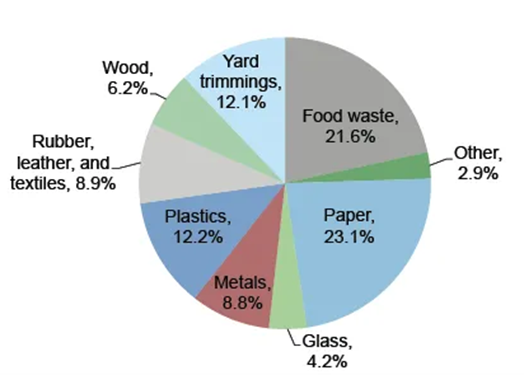

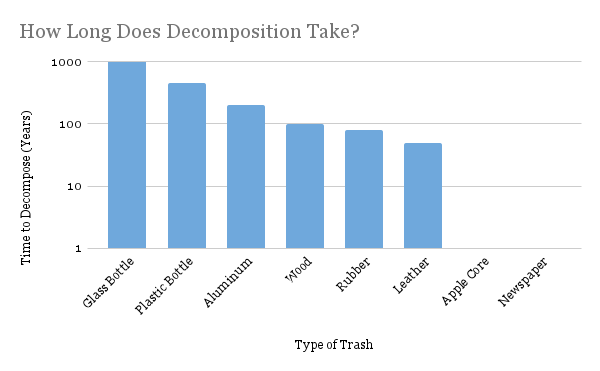

From Municipal Solid Waste Factsheet. Around 12% of waste is plastics, which is about half that of food and paper waste. However, food and paper waste take about a year or less to decompose (under the right conditions) and plastic waste can take 100s of years to decompose.

Mechanical Plastic Recycling

Mechanical plastic recycling refers to the multistep process of turning plastic waste into other plastic products of similar quality. New plastic is not created from raw materials, but rather from existing plastic. This creates a closed material loop, minimizing waste and the extraction of new natural resources. This is the traditional method of plastic recycling.

Although mechanical recycling works operationally, it isn’t economical. New plastic is cheaper and of higher quality than recycled plastic, and for these reasons, companies often choose to buy new plastic. Many recycling facilities accept plastics that they do not end up recycling because there is no buyer for the final product. Many plastics are also unsuitable for recycling because they are produced using toxic chemicals, which are used to create desired traits, like flexibility, in the final plastic product. These toxins can leach out during the recycling process and without expensive processes, they can harm both people and the environment.

The two most widely accepted types of plastic are PET#1 and HDPE#2. PET#1 includes water or soda bottles, and HDPE#2 plastics include milk jugs and shampoo bottles. They are recycled at rates of 20.9% and 10.3%, respectively.

Chemical Plastic Recycling

Chemical recycling of plastic is a relatively new process and refers to technologies of two categories: thermolysis and solvent-based processes. Both use a combination of heat, pressure, and other chemicals to break down old plastics to create fuel or chemicals. In theory, chemical recycling can process a wide variety of plastic types, making it an attractive alternative to mechanical recycling. However, no chemical recycling technique can process mixed waste from households, so the ability to recycle more plastic types requires sorting and individual processing for each plastic type, which is expensive and logistically challenging.

One important distinction between mechanical recycling and chemical recycling is that mechanical recycling creates new plastic products while chemical recycling techniques turn plastic into fuel or other chemicals. While chemical recycling does divert plastic waste from landfills, it does not currently offer manufacturers an alternative to creating new plastic from raw materials. Additionally, chemical recycling has little environmental benefit. The process of chemical recycling generates air pollution and greenhouse gases. Often, in plastic-to-chemicals plastic recycling, the end products are burned instead of converted into new plastic—making chemical recycling just incineration with more steps.

Chemical recycling has the potential to create high quality recycled plastics, but those techniques are still being developed and are not ready for commercialization.

Problems with Chemical Recycling

Chemical recycling is often framed as a solution for the plastic problem, but a majority of research and support has been funded by supporters of major oil, gas, and petrochemical corporations. Currently, the continued pursuit of chemical recycling does not offer a pathway towards sustainability due to the need to supplement new plastic production with other petrochemicals originating from fossil fuels extraction.

Most chemical recycling methods have not been proven to be environmentally beneficial or sustainable on an industrial scale. Research into chemical recycling often focuses on design innovation rather than operational performance or environmental outcomes. It is incredibly difficult to scale up from a laboratory to industrial setting while maintaining the desired result. Thus, most chemical recycling methods are only useful in theory.

In fact, a strong argument exists that chemical recycling is more environmentally damaging than mechanical recycling, because of its higher energy cost, larger carbon footprint, and increased toxic byproducts.

To create plastics with the needed material properties, a variety of substances are added to plastics. Many of these additives are toxic, including bisphenol-A (BPA), cadmium, benzene, brominated compounds, phthalates, lead, tin, antimony, and volatile organic compounds (VOCs). Many of these chemicals have been shown to cause cancer or harm bodily systems.

Chemical recycling that involves thermolysis breaks down the plastic molecules, making them even more harmful. For example, benzene and polycyclic aromatic hydrocarbons (PAHs), can be formed and released through this process. During the production process, these chemicals can move to become airborne, enter water sources, and then pose a threat to the health of those who drink polluted water. In 2019, 500,000 pounds of hazardous waste were reported from one chemical recycling facility alone.

New Experimental Chemical Recycling Methods

Researchers are always searching for ways to effectively recycle plastic and testing new technologies. One example of new research was conducted by scientists at the University of Michigan. Their study focused on PVC, a previously unrecyclable, heavy-duty plastic. When PVC is heated, a key step in mechanical recycling, it leaches toxic chemicals, including hydrochloric acid. The researchers discovered a way to break down PVC without adding heat. This electrochemical technique uses electrons to break the

bonds in the plastic. This way, the rate at which electrons are introduced to the system can be metered and the rate of hydrochloric acid production controlled. While promising, this technique does not generate new plastic and the Michigan scientists have not found uses for every part of the plastic.

Another new technology comes from the University of Texas and focuses on PET, one of the more commonly recycled plastics. The researchers used a machine learning model to bioengineer an enzyme capable of breaking down plastic in as little as a day. Within the study, the enzyme was able to break down plastic into small parts that can later be chemically reassembled into new plastics. Previous enzymes required high temperatures to operate, but this enzyme can break down PET at less than 50 degrees Celsius. This means it could be used to break down plastic outside of laboratory conditions. If this technology can be scaled up, it could be used to clean up landfills or polluted wilderness.

Recommendations

Given the complex economic, operational, and environmental nature of plastic recycling, both mechanical and chemical methods cannot solve the plastic waste problem alone. The best solution to the plastic waste problem is for individuals and industries to reduce plastic use, support policies that encourage reducing plastic use, and support methods of optimizing plastic to use as little as possible and use plastics that can easily be recycled. More information on plastic policy in Georgia can be found here.

Share this information with your legislator. Download the handout below.

References

American Chemistry Council. 2019. U.S. Chemical Investment linked to Shale Gas: $204 Billion and Counting (online). Accessed 7th January 2020. Available from: https://www.americanchemistry.com /Shale_Gas_Fact_Sheet.aspx

Center for Sustainable Systems, University of Michigan. 2021. “Municipal Solid Waste Factsheet.” Pub. No. CSS04-15. Available from: https://css.umich.edu/publications/factsheets/material-resources/municipal-solid-waste-factsheet

Greenpeace. (2022). Circular Claims Fall Flat Again (online). Accessed 8th April 2023. Available from: https://www.greenpeace.org/usa/wp-content/uploads/2022/10/GPUS_FinalReport_2022.pdf

Hopewell, J., Dvorak, R., Kosior, E. 2009. Plastics recycling: challenges and opportunities, Philosophical Transactions of the Royal Society B, 364, 2115-2126. doi:10.1098/ rstb.2008.0311

IPCC, 2018: Summary for Policymakers. In: Global Warming of 1.5°C. An IPCC Special Report on the impacts of global warming of 1.5°C above pre- industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change, sustainable development, and efforts to eradicate poverty (online). Accessed 8th January 2019. Available from: https://www.ipcc.ch/ site/assets/uploads/sites/ 2/2019/05/ SR15_SPM_version_report_L R.pdf

Laville, S. 2019. Founders of plastic waste alliance ‘investing billions in new plants’ (online). Accessed 14th February 2020. Available from: https:// www.theguardian.com/ environment/2019/jan/21/ founders-of-plastic-waste- alliance-investing-billions- in-new-plants

Patel, D., Moon, D., Tangri, N., Wilson, M. (2020). All Talk and No Recycling: An Investigation of the U.S. “Chemical Recycling” Industry. Global Alliance for Incinerator Alternatives. www.doi.org/10.46556/WMSM7198

Rollinson, A., Oladejo, J. (2020). Chemical Recycling: Status, Sustainability, and Environmental Impacts. Global Alliance for Incinerator Alternatives. doi:10.46556/ONLS4535

Sengupta, Somini. (2023). Guess What? More Plastic Trash (online). New York Times. Accessed 8th April 2023. Available from: https://www.nytimes.com/2023/02/07/climate/plastic-waste-recycling.html

Sherburne M. (2022). U-M Team Recycles Previously Unrecyclable Plastic (online). Michigan News. Accessed 8th April 2023. Available from: https://news.umich.edu/u-m-team-recycles-previously-unrecyclable-plastic/

Spierling, S., Knüpffer, E., Behnsen, H., Mudersbach, M., Krieg, H., Springer, S., Albrecht, S., Herrmann, C., Endres, H-J. 2018. Bio- based plastics – A review of environmental, social and economic impact assessments. Journal of Cleaner Production, 185, pp.476-491.

UT News. (2022). Plastic Eating Enzyme Could Eliminate Billions of Tons of Landfill Waste (online). Accessed 8th April 2023. Available from: https://news.utexas.edu/2022/04/27/plastic-eating-enzyme-could-eliminate-billions-of-tons-of-landfill-waste/

Waste Advantage Magazine (2017). How long does it take for garbage to decompose. Accessed 17 April 2023. Available from: https://wasteadvantagemag.com/how-long-does-it-take-for-garbage-to-decompose

Wong, S.L., Ngadi, N., Abdullah, T.A.T., Inuwa, I.M. 2015. Current state and future prospects of plastic waste as source of fuel: A review. Renewable and Sustainable Energy Reviews, 50, 1167-1180.